Blogs, E-fulfillment, New features, Warehousing, Warehousing

How voice picking makes you work faster, better and safer

Date

6 September, 2018

Reading time

4min. reading time

After reading all of the orderpick blogs, you are an expert on this subject. You have all the necessary knowledge to optimize the orderpick process. The warehouse is designed correctly and your order pickers almost have the perfect way of working down cold. Yet you see room for improvement. The process does not run smoothly, your employees ask for each other’s help every now and then and little mistakes are often made. But little mistakes for an order picker can have major consequences for your customers.

Order picking is error-prone

The orderpick process is fully focused on efficiency. This means that your pickers need to work fast and hard, while the task demands for accuracy as well. The combination of these two demands results in errors slipping through. Picking lists are misread, items are placed at the wrong customer or sometimes completely forgotten. Because of the hugeness of some tasks, watertight check-ups are almost impossible to achieve. And besides, this is extremely labor-intensive.

Think about your employees’ safety

When order picking, there can be no guarantee of your pickers’ safety. Their eyes are focused on the task list or scanner, so they do not see where they are going all the time. A crash is always possible this way. This is not only dangerous for your employees, but during a crash a lot of items can get damaged too. How can you eliminate these risks?

Voice picking

So, order picking needs to go faster, more accurate and safer. All of these features improve with voice picking. Together with our partners Honeywell and Dalosy, we worked hard to integrate voice picking with 3PL and Nekovri Dynamics.

What is voice picking?

With voice picking, the order picker picks up his orders by voice. A big surprise, right? It is really simple. All your employees need is a headset with a microphone. Via their headset they receive little tasks and thereafter they can easily confirm these tasks towards the Warehouse Management System. Your employees now have both their hands free and they do not have to look at their screen, so they can do their work more safely. Besides, their productivity improves up to a stunning 35%*. This means that within the same time frame, more orders can be picked.

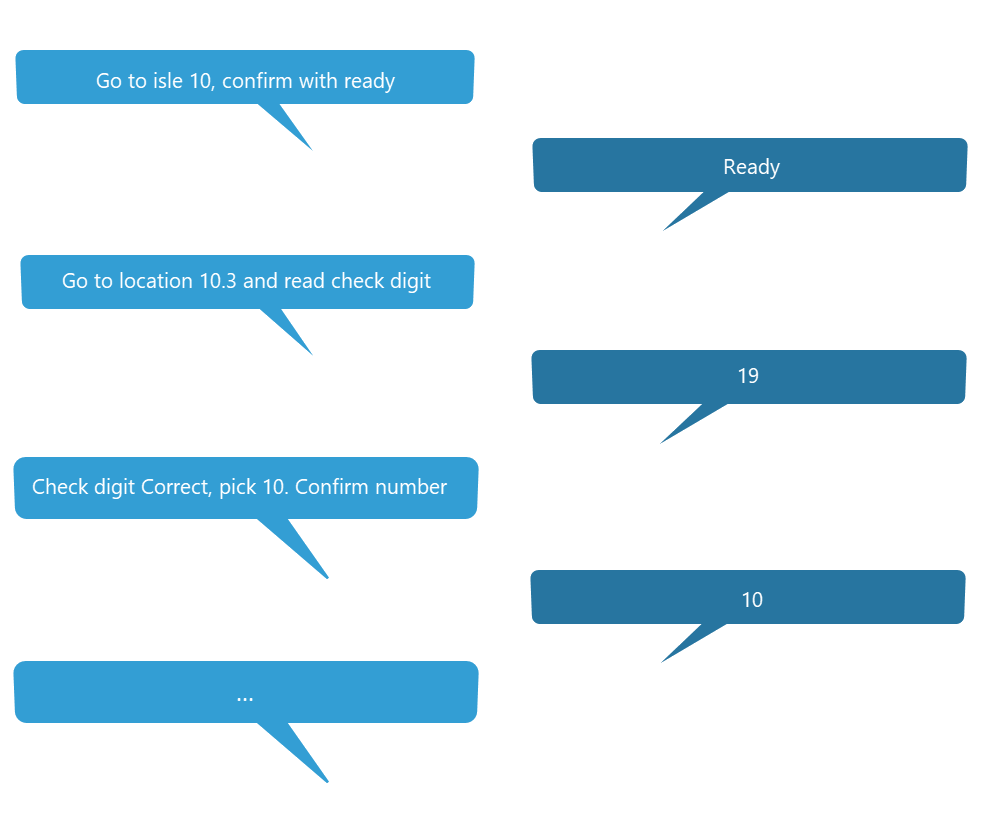

A task goes for example as following:

Reduce errors with 25%

By working with check digits or by letting the voice picker say the last numbers of the item code out loud, you are certain that the order picker is at the right location or item. Hereby, the number of errors can be reduced up to 25%*.

Do not waste time on training (temporary) employees

Are you working with many temporary employees? If so, voice picking can be the perfect solution for making them up and running in no time. Because of the spoken assignments, the system is highly intuitive. This way you do not need complicated training programs to train your employees anymore. Education tie can be reduced up to 50%* (!) this way.

How does the link between voice picking and Boltrics’ WMS work?

Quite simple. Voice picking is fully integrated with 3PL- and Nekovri Dynamics and can be – if desired – combined with our proven scan solution. Concerning voice picking, we make use of the Honeywell Vocollect system combined with Honeywell Hardware. You buy the voice terminals and headsets from Honeywell. Next, Boltrics ensures the bi-directional communication between your hardware and your WMS. Fully adjusted to your desires and without the need of customization. The process flows in your warehouse are completely designable in Dynamics NAV, which – thanks to our design – sometimes only takes 4 hours to configurate. Besides, it does not matter what language your employees speak. The solution supports multiple languages by default. For example, the popular languages within Dutch warehouses (Dutch, English and Polish) are standard available. This way, your employees can adjust their headset to their own preferences.

How does it work for your warehouse employees?

From the WMS you give your warehouse employees the concerning instructions for the items to be picked and the most efficient route. With every action your employee confirms directly to the system what he or she picked. Does it turn out that the order picker picked the wrong product, box or pallet? Then the system directly mentions this to your employee, so the right item still can be picked. Thus, you can achieve your colleagues in the warehouse working faster and more accurate – simply because they have their hands free.

*Statistics come from Honeywell https://www.honeywellaidc.com/